Unsupportive Support

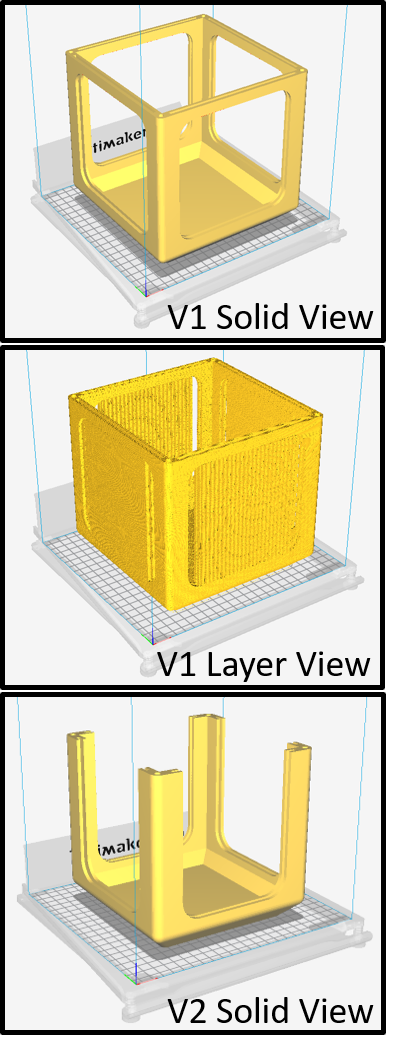

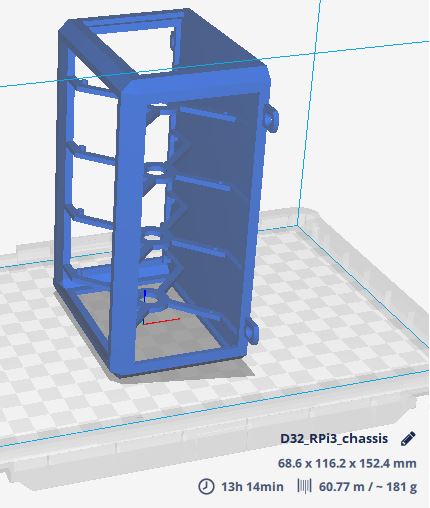

Keep in mind the capabilities of your 3D printer. Our V1 structure would’ve taken ~125 hours due to the support material needed as shown in V1 Layer View. We removed the cross beams in V2 which drastically cut down the print time since support material was not needed. These beams will be integrated into the top piece.

Last updated March 2019

3D printing has become mainstream. They are being used by just about anyone (hobbyists, engineers, scientists) and are found in any industry (automotive, aerospace, defense, medical, architecture, manufacturing, robotics). Why are they so appealing? Since their first release, the pricing has drastically decreased while the features, ease of use, quality, filament options, and versatility have increased. They allow you to build more prototypes in-house which result in faster turnaround times, lower costs, and higher margins. Things every company strives to achieve, if they want to stay in business.

My first 3D printer was relatively hard to use compared to the Dremel printer that we have now. It didn’t have any of the high-end features you see on 3D printers today such as auto bed leveling, enclosure, heated bed, WiFi connectivity, and automated filament loading. Although the technology has rapidly evolved, there are still some things that need to be considered when you’re printing complex structures. That is, the print time and support material.

Support material is used when you have an overhang in your part. Usually, the overhang angle is over 70 degrees, but you can customize this setting in the slicing software such as Cura. The more support material you need, the higher the print time will be. They are directly proportional. The orientation of your part can also affect the amount of support material needed.

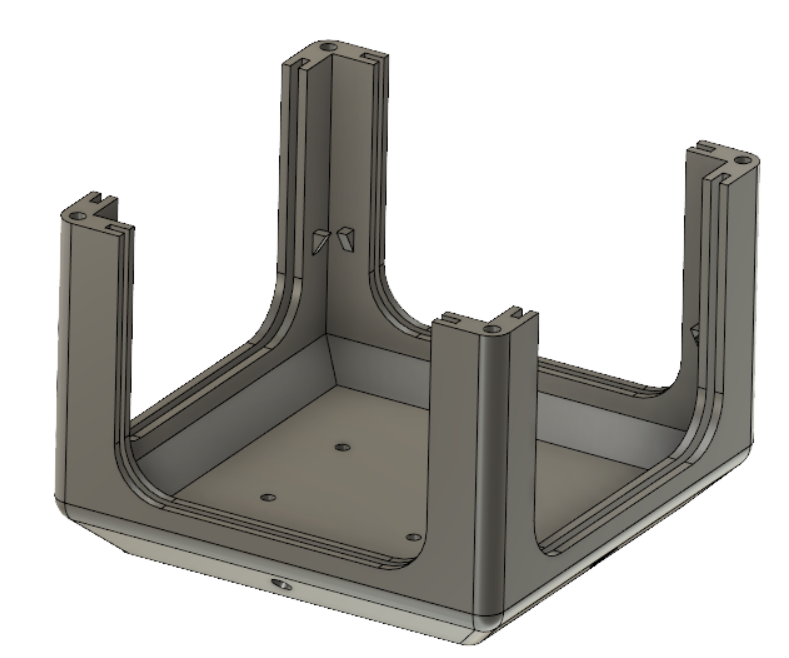

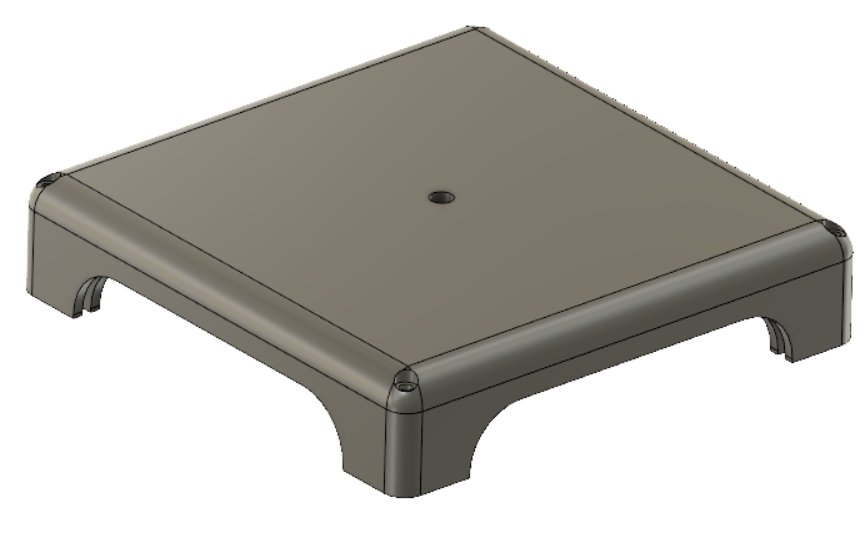

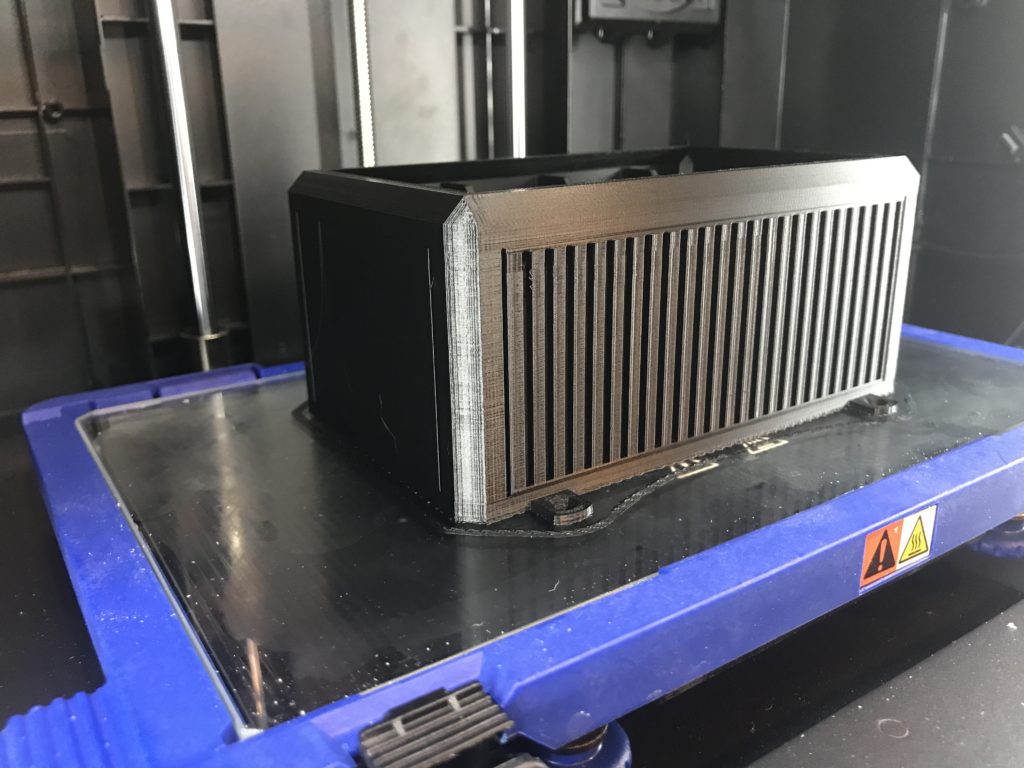

In our example, we were designing a weather balloon for a project. Our first version had overhangs at the top of the chassis on all four sides. This would have required a lot of support material. To fix this, we made the chassis a two-part design: 1) the bottom half where the hardware was mounted and 2) the top that screwed in to the bottom half. The bottom nor the top half didn’t need any support material so the print time was significantly reduced.

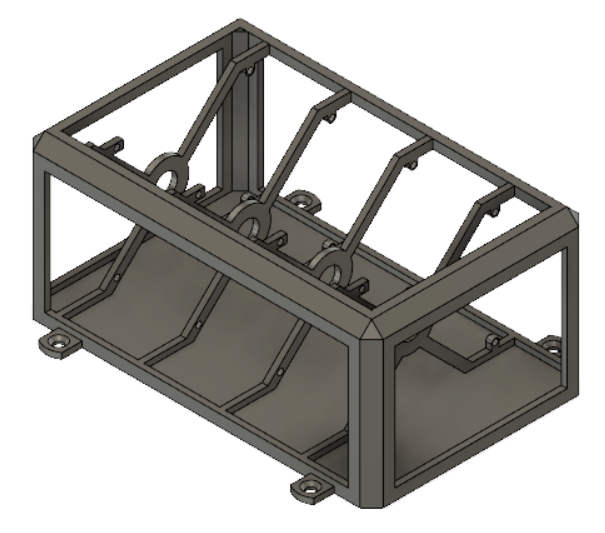

There are some instances where you can’t avoid the use of support material. Take a look at the chassis below. It would be hard to make it a two-piece design. You could design it in multiple pieces: one bottom, four vertical beams, and four horizontal beams. This would require you to come up with how the pieces will interconnect at each vertex. You would need minimal support material for that route.

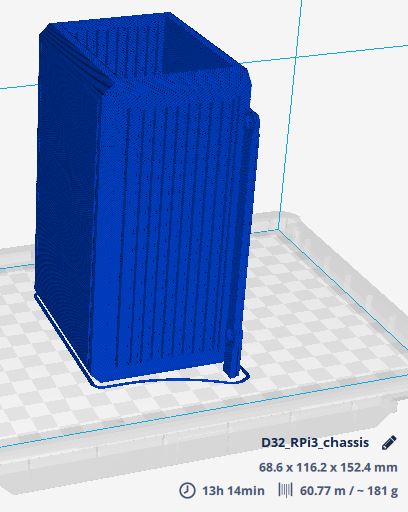

Changing the orientation wouldn’t help either – you would need even more support material if it was oriented as shown below. The print time also increased, going from 8.50 hours to ~13.25 hours. You have to weigh the pros and cons for each print.

What did we learn?

- 3D printers have decreased in price but have increased in functionality.

- Weigh the pros and cons for each part. Ultimately, you want to reduce material consumption and print time.